After lots of research on different air compressor setups (York, Sanden, ARB single & twin, VIAir, Cigarette lighter style, etc.), I found that none of them fit my specific needs. Of the options, I believe the York or Sanden is my favorite, but the cost and amount of work required seem unnecessary for my needs - mostly just to air up when driving my TJ on the beach.

After weighing my options, and realizing there are numerous companies selling the same compressor just rebranded and up-charged, I decided to run a modified NAPA air compressor. This appears to be the cheapest option for that style compressor, which will fit my needs very well. Some of the downsides, that I have corrected, are the lack of standard NPT air fittings, a pressure switch (which I have seen some on the forum call unnecessary), poor pressure gauge on the supplied hose and alligator clamp battery cables (on what I would call undersized wiring).

I have seen many posts about people attempting to figure out the best way to make their compressor removable when not off-roading, and I believe my setup works very well for this situation. The TJ is also my daily driver and the way in which it is wired and located in the trunk makes removal very easy for those rare times you need a little more trunk space.

Modifications to NAPA Compressor:

- Installed 85 - 100 PSI Pressure Switch

- Replaced the Nitto style fittings with 1/4" NPT fittings

- Removed the original circuit board and power cables

- Installed a 200 AMP relay in it's place to make running my new power cables much easier

- Installed new On/Off switch on the front side of compressor (Originally on the back)

- Installed high quality 4 Gauge AWG welding/battery with Anderson style connectors

Wiring to Battery:

- I ran the new 4 gauge cable, with an 120 AMP Anderson connector on the back end, from the trunk to the battery

- I routed it along the factory wiring harness on the driver side and ran it through a grommet near the clutch pedal

- Installed a Blue Sea Systems Marine Style Fuse Block, with an 125 AMP fuse (it is a 90 AMP compressor) - thank you @flyinfish for the recommendation

- Finished it all up in some nice wire loom and wired it to the battery

4 Tire Inflation/Deflation System:

I also read many posts about the uselessness of 4 tire inflation systems - many people citing that they are a waste since they "take just as long", "require tons of time to untangle the hoses" and "take up too much space". I find all those complaints to be warrantless - so I made a manifold with a ball valve, pressure gauge and two quick disconnects so that I can inflate/deflate one side of the Jeep if I wanted to. After making the system and timing the results, I believe these claims are even more invalid and the fact that I don't have to bend over at each tire for a period of time is another benefit.

From sitting in my driver seat, setting up the hoses, airing down, putting everything away and back in the driver seat - 4:15 seconds (35 PSI to 17 PSI)

From sitting in my driver seat, setting up the hoses, airing up, putting everything away and back in the driver seat - 4:54 seconds (17 PSI to 35 PSI)

All in on the hose and manifold system was around $150 dollars. The ARB tire deflator is ~ $60 and requires, in my mind, much more work each time so I don't mind the extra cost.

Summary:

I'm very happy with how the modifications, hose system and install went. I will be attaching pictures below but I believe it is a very clean install and a great budget option for those who aren't out wheeling every weekend of the year. The entire setup cost me somewhere around $400, including the hose system, which is about how much I would be in for an ARB single without the 4 tire system.

Lastly, I wanted to point out that I did not come up with all of this myself - many videos have been made about installing a pressure switch to these style compressors - but IronsideAdventures801 on YouTube has done a phenomenal job on the modifications and tire inflation system (and he also has a TJ). A very small channel filled with excellent videos, I would highly recommend checking him out. I did not follow what he did exactly, but it is quite similar - I changed a few things to better fit my needs.

Pictures:

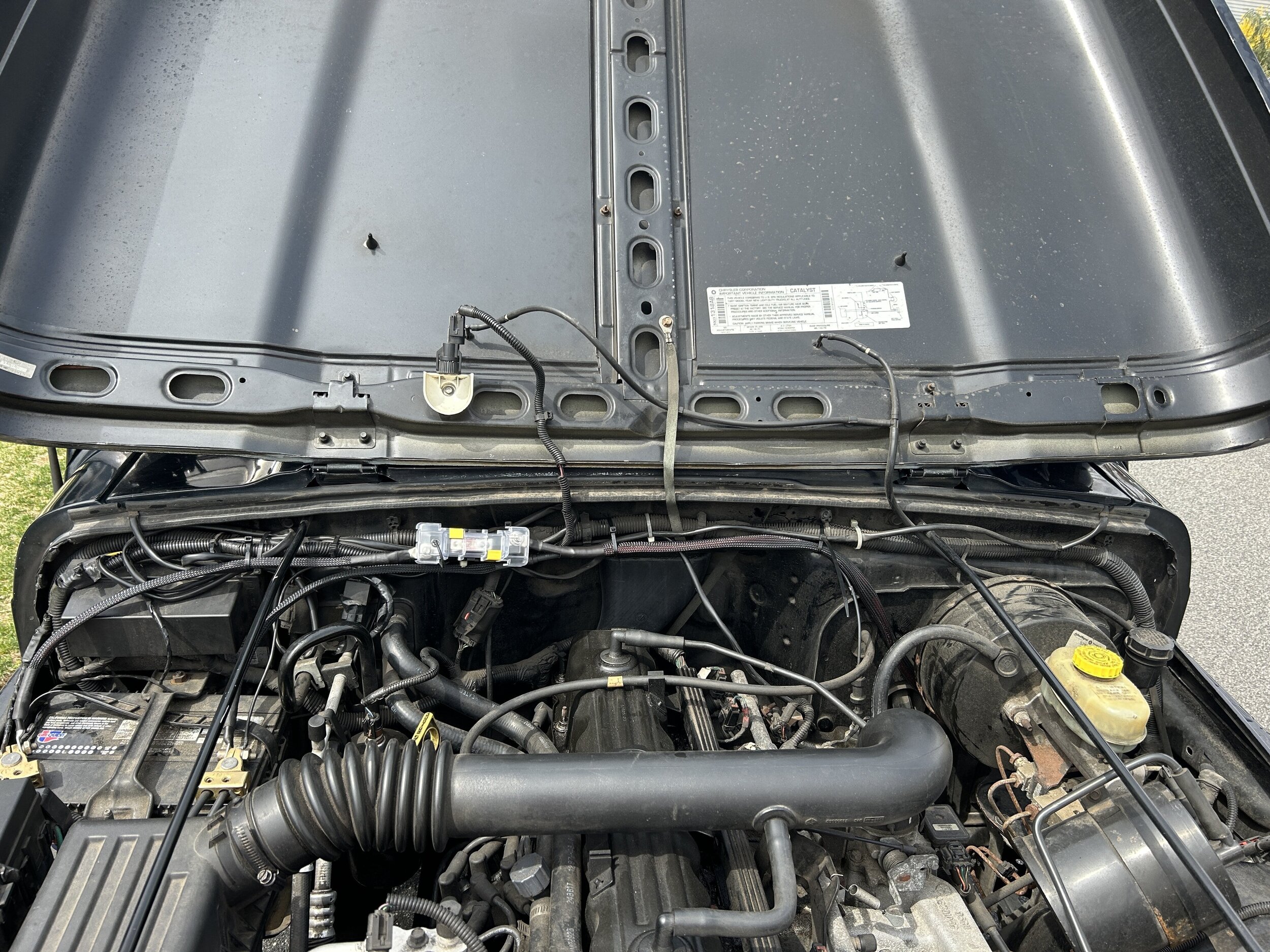

The wiring to the compressor has the large fuse and runs below the brake booster

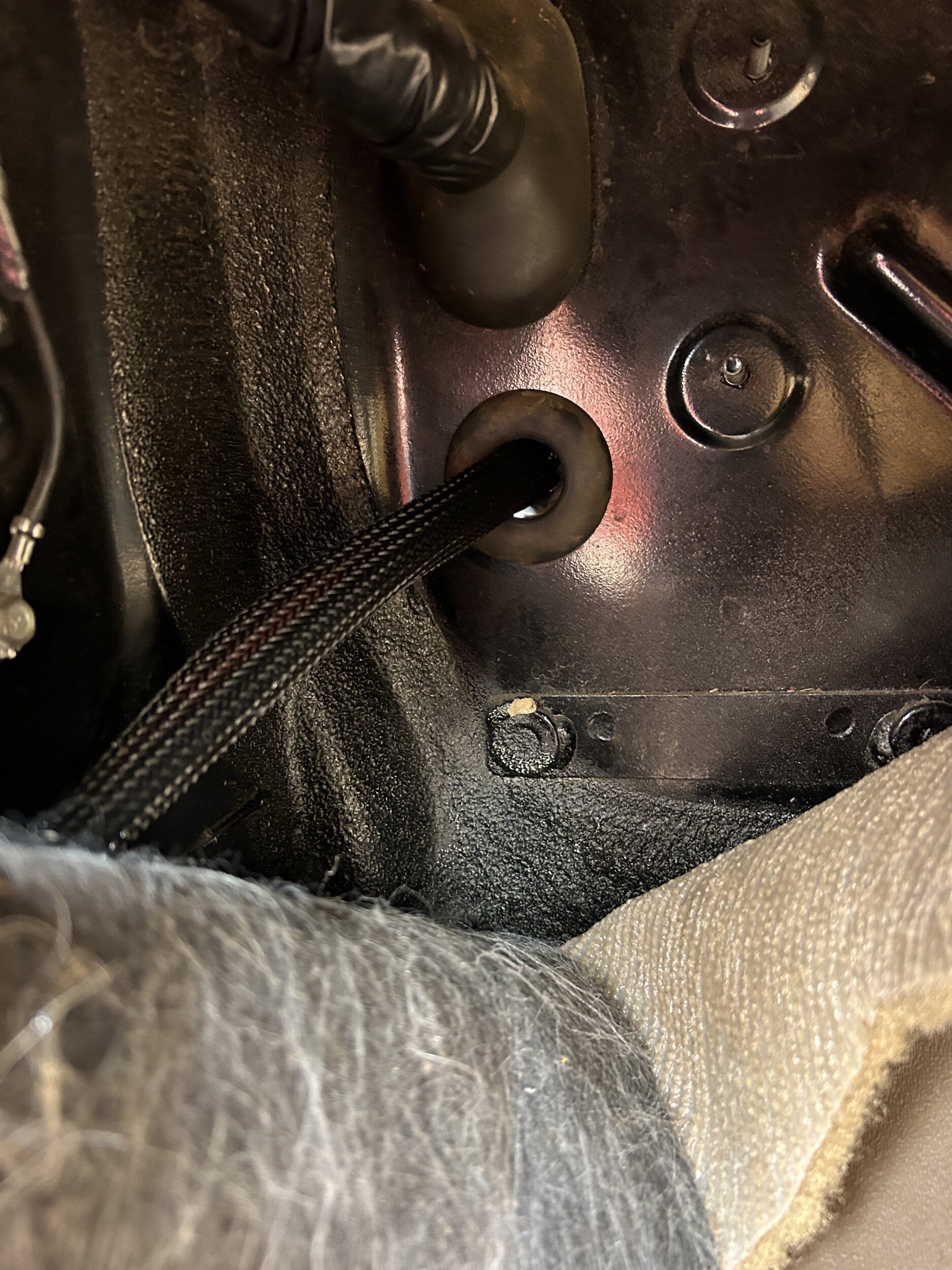

The wiring runs through the grommet near the bottom of the fire on the driver side

Along the factory wiring on the tub of the driver side

The wiring ends at an Anderson style connector right behind the rear driver side seat belt

Front side of the compressor with new switch installed

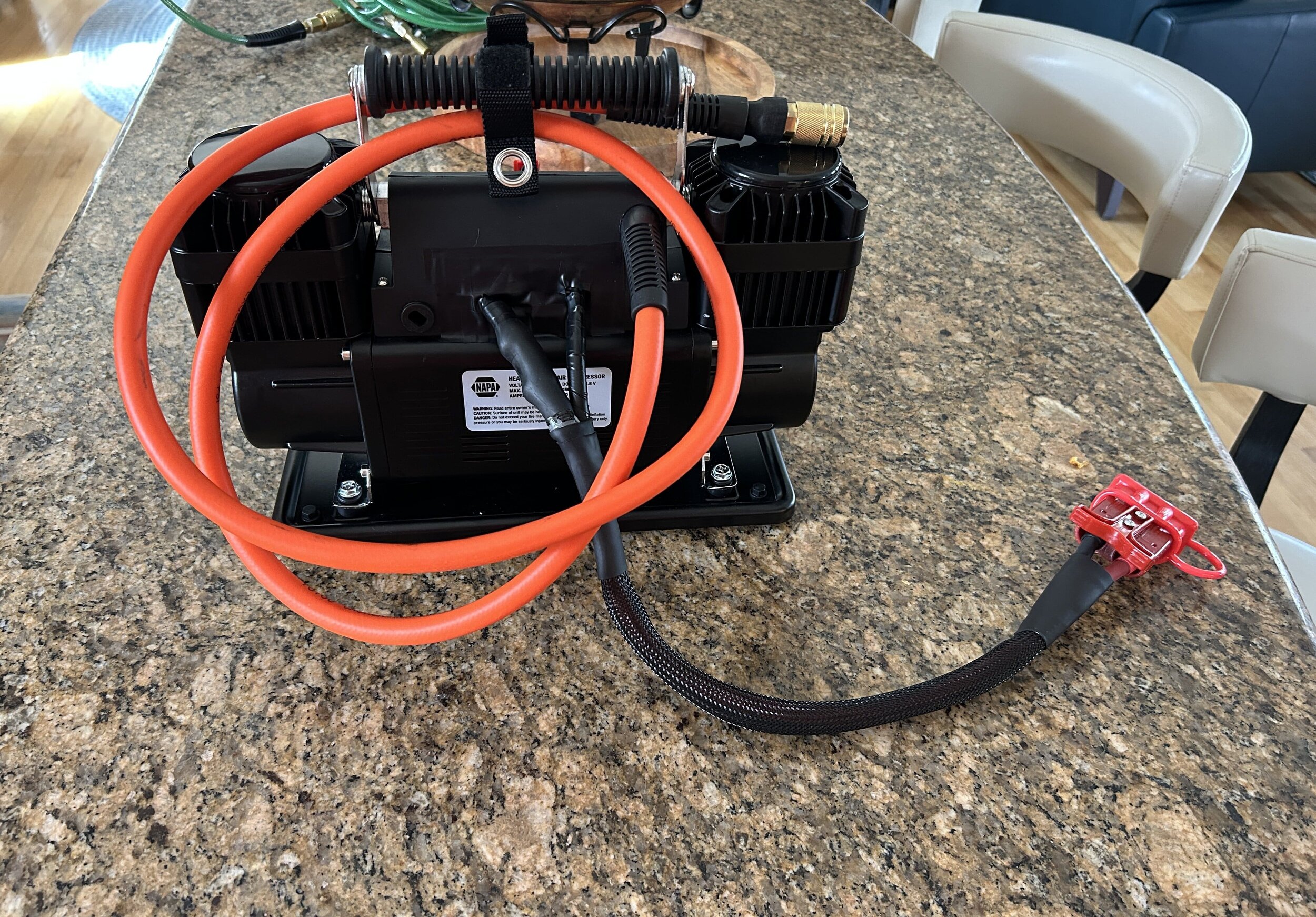

Backside of compressor with new 1/4" NPT hose and Anderson style connector to plug into the wiring to the battery

Hose setup

Hose setup

Hope someone may find this useful if they find themselves looking into a budget friendly compressor. I know most people prefer to mount their air compressors under the hood but I feel a bit safer with it being somewhat more protected from the elements (not to say my trunk doesn't leak in the rain).

After weighing my options, and realizing there are numerous companies selling the same compressor just rebranded and up-charged, I decided to run a modified NAPA air compressor. This appears to be the cheapest option for that style compressor, which will fit my needs very well. Some of the downsides, that I have corrected, are the lack of standard NPT air fittings, a pressure switch (which I have seen some on the forum call unnecessary), poor pressure gauge on the supplied hose and alligator clamp battery cables (on what I would call undersized wiring).

I have seen many posts about people attempting to figure out the best way to make their compressor removable when not off-roading, and I believe my setup works very well for this situation. The TJ is also my daily driver and the way in which it is wired and located in the trunk makes removal very easy for those rare times you need a little more trunk space.

Modifications to NAPA Compressor:

- Installed 85 - 100 PSI Pressure Switch

- Replaced the Nitto style fittings with 1/4" NPT fittings

- Removed the original circuit board and power cables

- Installed a 200 AMP relay in it's place to make running my new power cables much easier

- Installed new On/Off switch on the front side of compressor (Originally on the back)

- Installed high quality 4 Gauge AWG welding/battery with Anderson style connectors

Wiring to Battery:

- I ran the new 4 gauge cable, with an 120 AMP Anderson connector on the back end, from the trunk to the battery

- I routed it along the factory wiring harness on the driver side and ran it through a grommet near the clutch pedal

- Installed a Blue Sea Systems Marine Style Fuse Block, with an 125 AMP fuse (it is a 90 AMP compressor) - thank you @flyinfish for the recommendation

- Finished it all up in some nice wire loom and wired it to the battery

4 Tire Inflation/Deflation System:

I also read many posts about the uselessness of 4 tire inflation systems - many people citing that they are a waste since they "take just as long", "require tons of time to untangle the hoses" and "take up too much space". I find all those complaints to be warrantless - so I made a manifold with a ball valve, pressure gauge and two quick disconnects so that I can inflate/deflate one side of the Jeep if I wanted to. After making the system and timing the results, I believe these claims are even more invalid and the fact that I don't have to bend over at each tire for a period of time is another benefit.

From sitting in my driver seat, setting up the hoses, airing down, putting everything away and back in the driver seat - 4:15 seconds (35 PSI to 17 PSI)

From sitting in my driver seat, setting up the hoses, airing up, putting everything away and back in the driver seat - 4:54 seconds (17 PSI to 35 PSI)

All in on the hose and manifold system was around $150 dollars. The ARB tire deflator is ~ $60 and requires, in my mind, much more work each time so I don't mind the extra cost.

Summary:

I'm very happy with how the modifications, hose system and install went. I will be attaching pictures below but I believe it is a very clean install and a great budget option for those who aren't out wheeling every weekend of the year. The entire setup cost me somewhere around $400, including the hose system, which is about how much I would be in for an ARB single without the 4 tire system.

Lastly, I wanted to point out that I did not come up with all of this myself - many videos have been made about installing a pressure switch to these style compressors - but IronsideAdventures801 on YouTube has done a phenomenal job on the modifications and tire inflation system (and he also has a TJ). A very small channel filled with excellent videos, I would highly recommend checking him out. I did not follow what he did exactly, but it is quite similar - I changed a few things to better fit my needs.

Pictures:

The wiring to the compressor has the large fuse and runs below the brake booster

The wiring runs through the grommet near the bottom of the fire on the driver side

Along the factory wiring on the tub of the driver side

The wiring ends at an Anderson style connector right behind the rear driver side seat belt

Front side of the compressor with new switch installed

Backside of compressor with new 1/4" NPT hose and Anderson style connector to plug into the wiring to the battery

Hope someone may find this useful if they find themselves looking into a budget friendly compressor. I know most people prefer to mount their air compressors under the hood but I feel a bit safer with it being somewhat more protected from the elements (not to say my trunk doesn't leak in the rain).