I have failed to install Undecover Fabworks aluminum engine skid. It is too narrow under my transmission oil pan. Trimming side bends is not an option, as it would not be stiff enough to land on.

If anyone wants a crudely spray painted black aluminum UCF skid with some better hardware included, will give a good price. Shipping charge should be reasonable given it is aluminum.

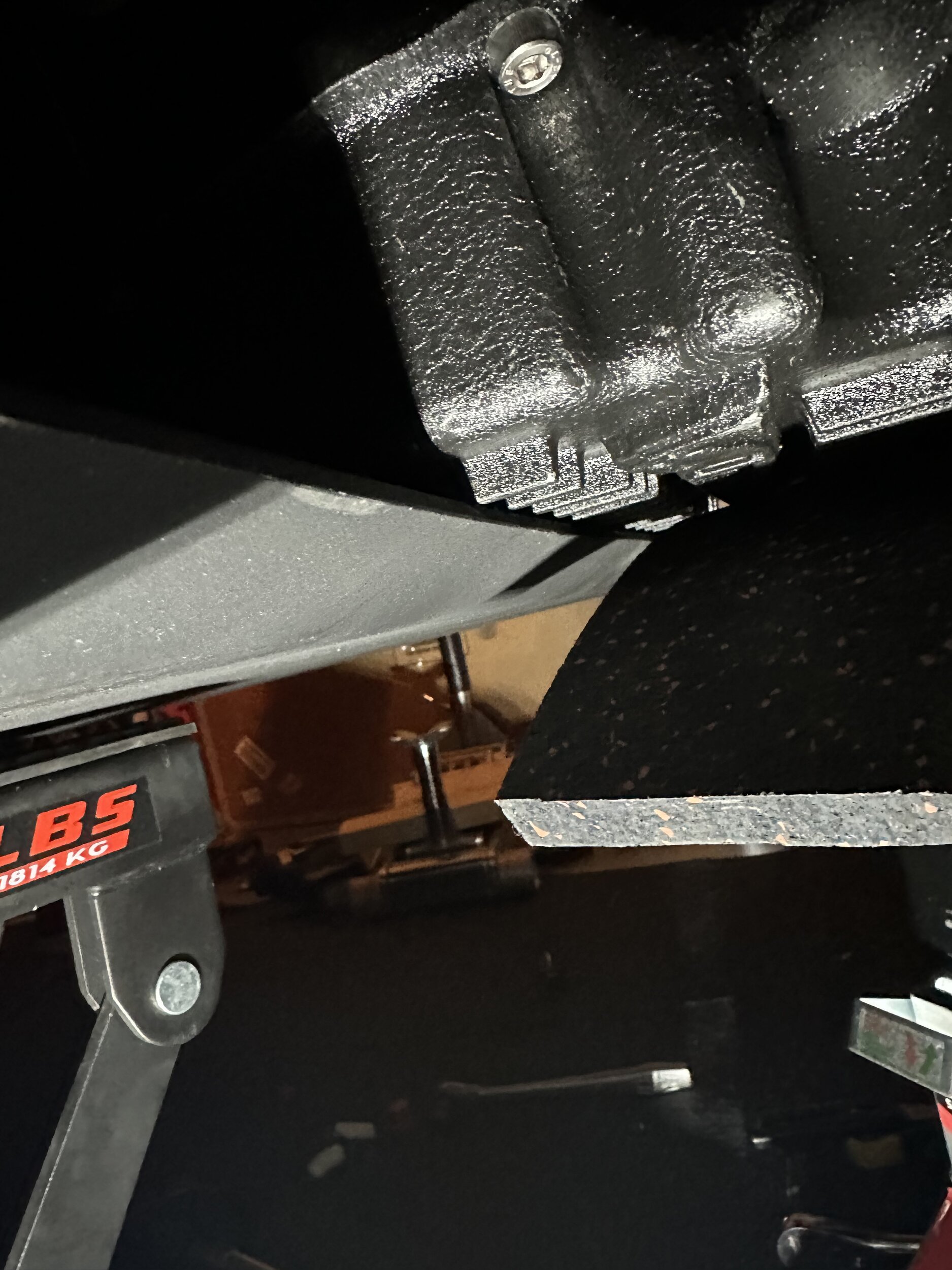

Improved hardware - as whatever is included with it is some worst I have ever seen. Are bolts made of cheese?

Split washers torqued to 35ft-lb not supposed to do that. Replaced with grade 8 from a bolt kit I have.

View attachment 500666

I will try to put back the short stock if it can protect the transmission oil pan, and investigate what can be done for engine oil pan. Either find a wider steel long one that fits - M.O. R.E. One looks promising. Or just do separate oil pan skid from Metalcloak or someone else.