Thanks for the help, Guys. Still the best forum out there.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nashville TJ's Build - Continued

- Thread starter NashvilleTJ

- Start date

Thanks for the help, Guys. Still the best forum out there.

Jerry would have solved it for you yesterday if he were still here.

Correct.

What is the benefit of a test light over a voltmeter?

Testing voltage on an open circuit is useless. You could have 1 strand of wire connected and still read B+. You could also have thousands of ohms of resistance and still measure B+. Measuring voltage with a dvom is only a useful test on a live circuit.

By using a test light you are loading the circuit to ensure you are “getting voltage” that can pass current. Still not a great test as a test light is usually .25 amp. I’m sure the motor pulls much more than that.

It also looks like the locking tab on the connector is not functioning, which may explain how it came loose. 20 year old vehicle, I guess…

So maybe Hickam's dictum?

It’s definitely convenient, and also has a bunch of multi-meter like features.

So I’m sitting here eating lunch, contemplating all this, and thinking: “I can’t believe I put a Hemi in this thing, and I’m having trouble fixing a fucking wiper motor…”

Why not convert to manual wipers? I hear they work real good in the bathroom.

A quick fab project this morning.

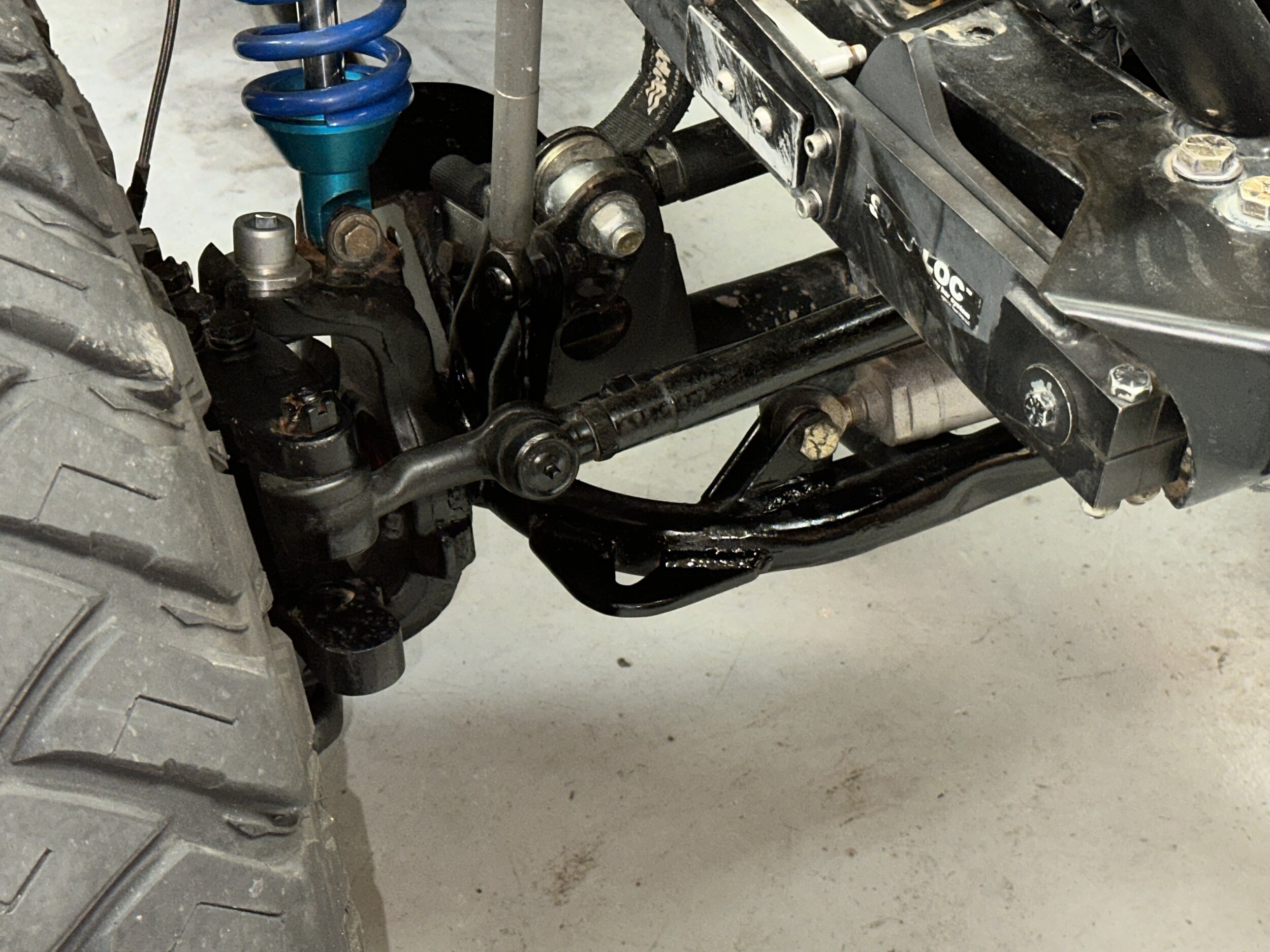

I trailer the rig a lot, so I like to make it as easy and quick as possible to strap the rig down. In the rear, I put these tabs on the axle housing, which makes it very quick to clip on the straps. Not having to loop a strap around the axle shaft keeps me from having to climb under the rig.

It's made from 3/8" plate, and works very well (and yes, it needs some paint... )

)

On the front, I still have to throw a strap around the tube that serves as the hydro cylinder mount and guard. Not too difficult to do, but a minor pain (as pains go).

So having an urge to get out the heavy-duty power tools, today I remedied the pain.

I trailer the rig a lot, so I like to make it as easy and quick as possible to strap the rig down. In the rear, I put these tabs on the axle housing, which makes it very quick to clip on the straps. Not having to loop a strap around the axle shaft keeps me from having to climb under the rig.

It's made from 3/8" plate, and works very well (and yes, it needs some paint...

On the front, I still have to throw a strap around the tube that serves as the hydro cylinder mount and guard. Not too difficult to do, but a minor pain (as pains go).

So having an urge to get out the heavy-duty power tools, today I remedied the pain.

Last edited:

Breaking out my mad CAD skills, I came up with this tab which will accept my strap clips and weld to the tube...

...like this:

...and this:

...like this:

...and this:

Last edited:

I had a small piece of 3/8" plate in my metal bin, and it was just big enough to yield two brackets.

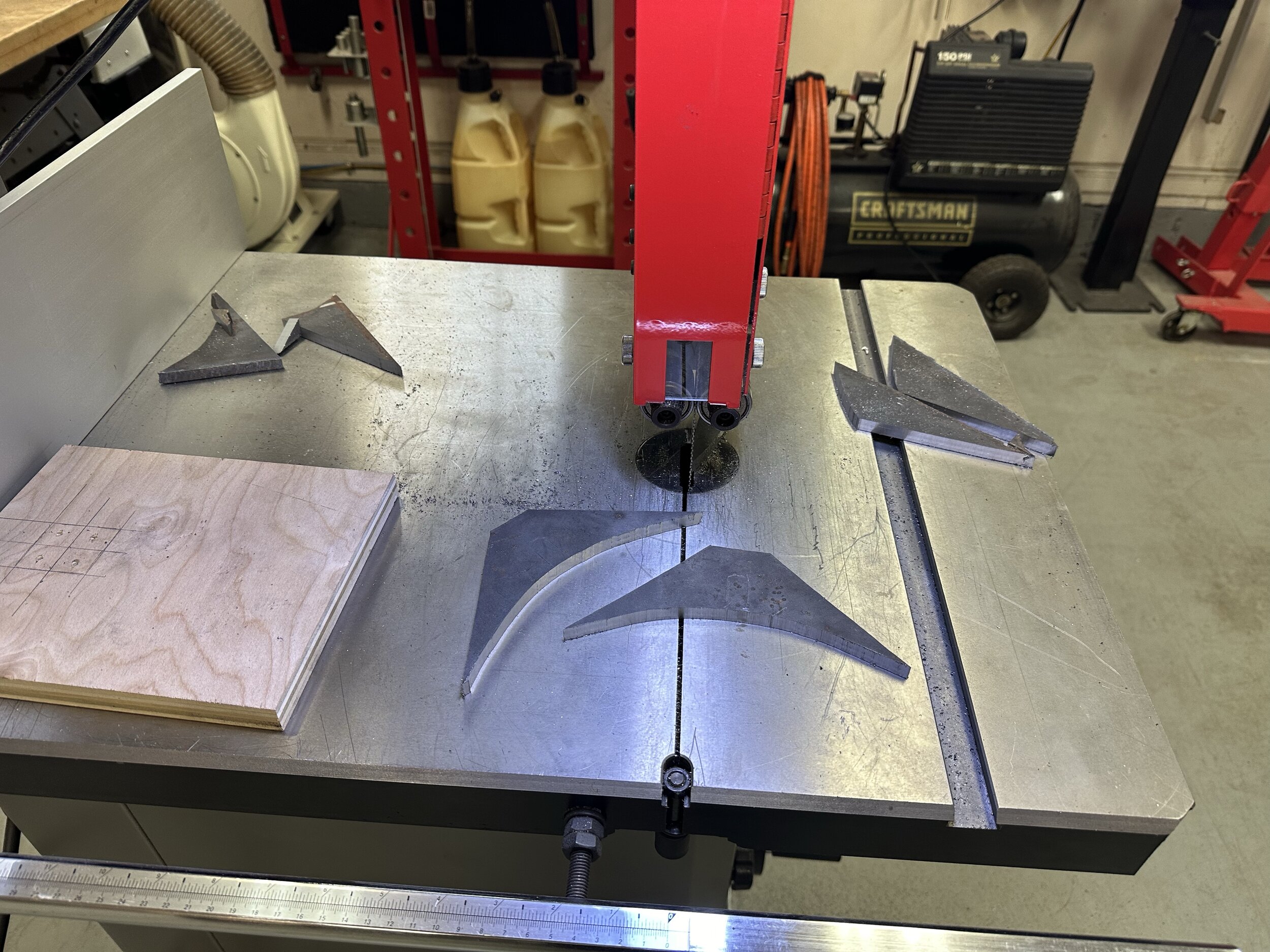

And out came the big band saw.

You can't beat this thing for making short, accurate work of this kind of cut. Just like that, I had my two blanks.

And out came the big band saw.

You can't beat this thing for making short, accurate work of this kind of cut. Just like that, I had my two blanks.

Breaking out my mad CAD skills, I came up with this tab which will accept my straps clips and weld to the tube...

View attachment 524110

...like this:

View attachment 524111

...and this:

View attachment 524112

Very COOL

To make the slots which receive the clips, I first cut a 1/2" hole at the top to make a rounded end, and therefore avoid any sharp edges which would result in a stress riser. Probably would not make a difference here, but it does look much nicer.

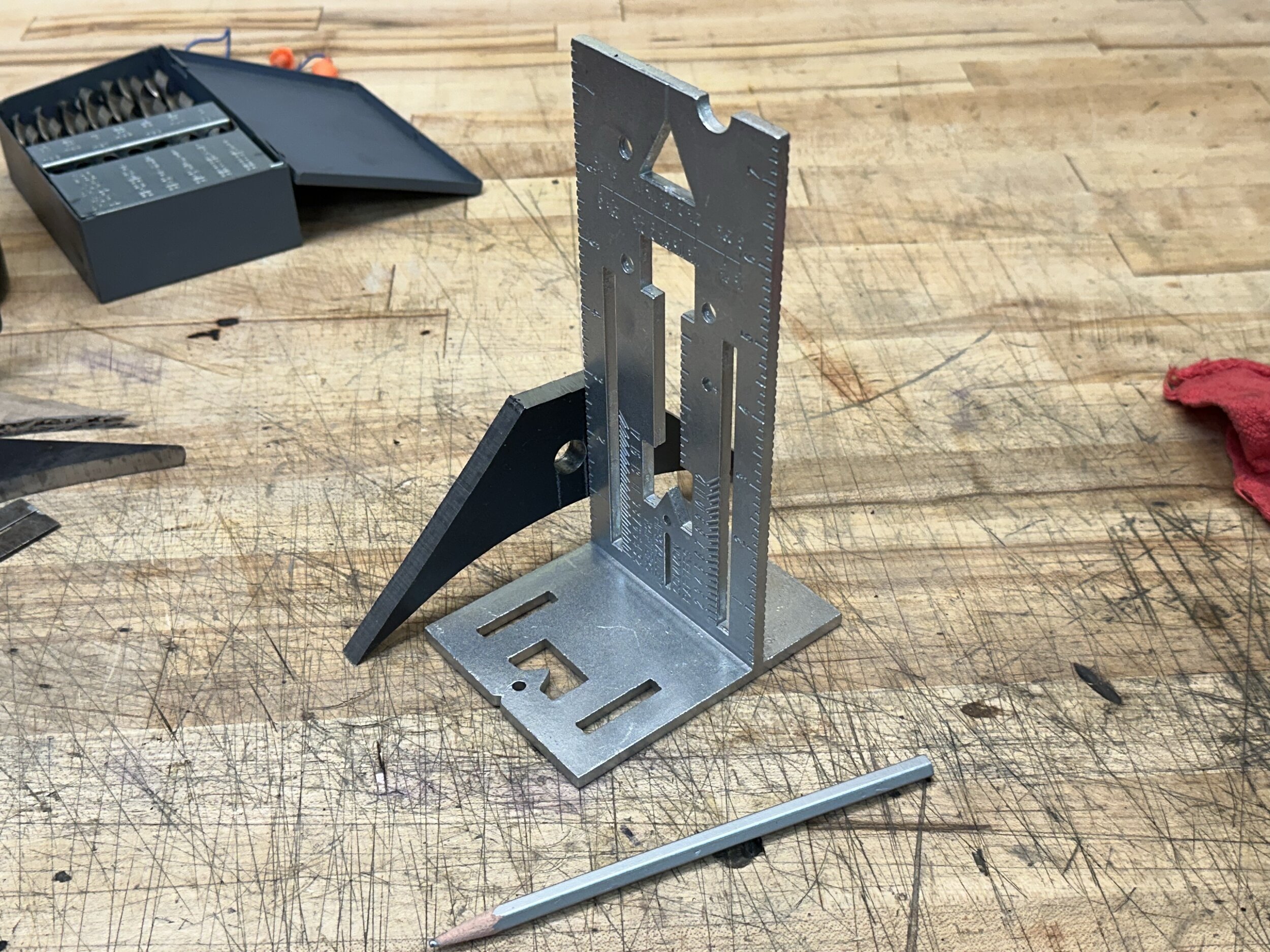

A few days ago, over on the "Favorite Tools" thread, @mrblaine posted this cool combination square - I picked one up the same day. And this morning, I put it to good use marking the slots.

A few more quick cuts on the band saw, some work with the flap wheel, and the brackets were complete.

A few days ago, over on the "Favorite Tools" thread, @mrblaine posted this cool combination square - I picked one up the same day. And this morning, I put it to good use marking the slots.

A few more quick cuts on the band saw, some work with the flap wheel, and the brackets were complete.

And now the fun part - tacking in place and checking the fitment.

Everything looked good, so I finish welded both tabs in place:

And here it is with the strap connected.

I pulled on the strap as hard as I could, and the bracket did not tear out of the tube. Some I'm happy with the strength...

And finally, a little paint:

Well, actually a lot of paint. I've been needing to deal with a bit a surface rust all over the underside since running in the snow earlier this year, so I took advantage of the opportunity.

And that's it. It will be soooo much easier to strap down the rig now.

OK, so small victories...

Everything looked good, so I finish welded both tabs in place:

And here it is with the strap connected.

I pulled on the strap as hard as I could, and the bracket did not tear out of the tube. Some I'm happy with the strength...

And finally, a little paint:

Well, actually a lot of paint. I've been needing to deal with a bit a surface rust all over the underside since running in the snow earlier this year, so I took advantage of the opportunity.

And that's it. It will be soooo much easier to strap down the rig now.

OK, so small victories...

I use the big rubber tabs on the ends of the axles to strap to

The tow-pig got some attention this week:

What kind of setup are you installing? Just bags with valves or a full onboard air system?

What kind of setup are you installing? Just bags with valves or a full onboard air system?

You don't really think he's the kinda guy to stop with a couple shrader valves on his bumper do you?

You don't really think he's the kinda guy to stop with a couple shrader valves on his bumper do you?

If I was a betting man, no, I'd guess full on board system with individual bag control from inside. With a hint of...

But just shy of...

What kind of setup are you installing? Just bags with valves or a full onboard air system?

I also put in an Airlift WirelessAir system. It's similar the system I had in the old tow-pig.

https://www.etrailer.com/Air-Suspension-Compressor-Kit/Air-Lift/AL74000EZ.html

Although similar, the bags I put in are 7" (diameter) bags. The old set were 5" I believe. These lift a bunch more with less pressure.

You don't really think he's the kinda guy to stop with a couple shrader valves on his bumper do you?

Well, actually...

My remodeling company builds all its’ cabinets in house- and we build a lot of them...takes 2 separate shops to support it all-

That is good work you have going on.

My last truck was set up like that and never had issues. Current truck I'd like to get some longer travel bags.the ones in it get pulled tight regulary. Might be why i keep getting leaks from them. Maybe like these?

https://www.pmfsuspension.com/2017-22-SD-Long-Travel-Overload-Bag-Kit_p_231.html